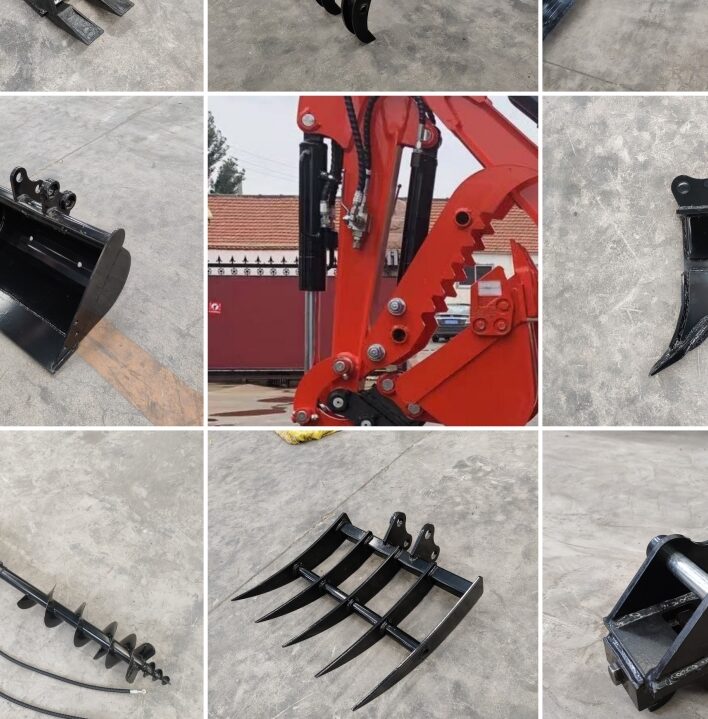

Attachments, Construction Equipment, Mini-Excavator, Spare Parts, TYPHON Machinery

Best Mini Excavator Buckets: 5 Top Trending

One of the most important things is to have the right bucket to perform any task efficiently and effectively when using a mini-excavator. There are several types of buckets, each made for specific tasks, depending on various sizes and designs. Using the right bucket will not only increase you work’s speed but also improve quality.

Whether digging trenches, clearing debris, or leveling ground, choosing the right bucket can make all the difference in your work’s speed and quality.

In this guide, we’ll explore the top 5 buckets for your mini-excavator and the tasks each one best suits. Understanding their differences will help you make an informed choice when purchasing or switching buckets.

Best Mini Excavator Buckets

1. Digging Bucket

This is among the most often used mini excavator buckets, also known as the digging bucket. There is no better equipment for general-purpose digging and excavation purposes than a digging bucket and it has strong teeth, which make it suitable for breaking through tough ground and enduring rocks or some other obstacles.

Best for:

- General digging tasks

- Trenching

- Breaking through tough soil or rocky ground

Features:

- Durable construction with reinforced edges

- Teeth for breaking through rigid materials

- Available in many sizes depending on your need

Why it’s essential:

This digging bucket is necessary if you want to dig most of your stuff because It’s built for strength and efficiency; you can use it to get anything done quickly.

2. Grading Bucket

A grading bucket, also known as a cleanup bucket, is designed for tasks that require smoothing, leveling, or cleaning up large areas of dirt or debris. Unlike the digging bucket, the grading bucket typically has a more comprehensive, flat edge with no teeth, which makes it perfect for spreading material evenly and achieving a smooth finish.

Best for:

- Smoothing and leveling ground

- Cleaning up work areas

- Spreading dirt, gravel, or sand evenly

Features:

- Flat, wide edge for even distribution of materials

- Available in wider sizes to cover more ground

- No teeth, making it ideal for fine-grading tasks

Why it’s essential:

The grading bucket is perfect for finishing jobs that require a smooth, clean surface. Whether preparing an area for landscaping or cleaning up after a digging project, this bucket will help you get professional results.

3. Trenching Bucket

The trenching bucket is specifically designed for digging narrow, deep trenches. Its slim and longer-than-usual design allows you to create precise trenches for pipes, cables, or drainage systems. The bucket usually has sharp teeth for cutting through tough soil, which makes it efficient for trenching work.

Best for:

- Digging trenches for utility lines or drainage

- Installing pipes and cables

- Working in narrow spaces

Features:

- Narrow design for precise trenching

- Sharp teeth for efficient digging

- It comes in many sizes depending on the requirements

Why it’s essential:

If your project includes laying pipes or placing cables, a trenching bucket can dig the perfect trench without the time nor the effort that digging with shovels would require. Designed for clean, narrow cuts with minimal material removal, it’s the professional’s partner in the world of tree cutting.

4. Tilting bucket

The tilting bucket is a highly versatile attachment that allows you to tilt it at different angles and makes it easier to work on uneven ground or around obstacles, so It’s perfect for jobs requiring precise excavation angle or grading control. This bucket can rotate up to 45 degrees in either direction, giving you more flexibility than a standard bucket.

Best for:

- Grading on uneven terrain

- Digging around obstacles

- Precision excavation work

Features:

- Tilts up to 45 degrees for greater flexibility

- Controlled hydraulically for precise movements

- Ideal for working on sloped or uneven surfaces

Why it’s essential:

The tilting bucket is a game-changer for jobs that require more control and precision because It allows you to adjust the bucket’s angle on the fly, and making it easier to work in challenging environments without constantly repositioning the excavator.

5. V-Bucket (V-Shaped Bucket)

A v-bucket is used for making V-shaped digging, and the V-shaped cutaway on this bucket makes it a good bucket for digging drainage holes and putting in pipes; additionally, its pointy shape makes clean cuts and reduces the amount of removed material.

Best for:

- V-shaped holes

- drainage lines

- digging ditches to manage water.

Features:

Its V-shaped curve makes it good at digging precise trenches, which makes it the best choice for jobs that require putting pipes or draining water.

Why it’s essential:

A V-bucket will save you a lot of time and work because Its shape is special to ensure a clean, neat, and precise cut.

How to Choose the Right Bucket for Your Mini-Excavator

Overall, the bucket you choose for your mini excavator depends on the type of tasks you want to work on. Consider the following when making your decision:

Type of Work: Are you digging, grading or trenching? If yes then there is a specific bucket for every task to make the perform this task easier and faster.

Soil Conditions: you’ll need a digging bucket specifically if you need to work in tough or rocky areas. Softer or looser soil will be best suited using a smooth bucket, such as a grading bucket.

Bucket Size: The scale of the job should match the bucket size, for example a giant bucket will move more for a task and not be suitable for smaller, more precise jobs. Find the right size for the job.

Excavator Capacity: The bucket must be the same size as your mini excavator. There are some buckets that are too heavy or too large for machines.

Maintenance Tips for Mini Excavator Buckets

After choosing a bucket perfect for your needs, maintain its condition properly to extend its health and get the most out of its potential:

Inspect for Wear and Damage: Periodically inspect your bucket for cracks, dents, or worn teeth. You will avoid more costly repairs later on by keeping these points in mind.

Clean After Use: When working in muddy conditions, dirt and debris can build up. After each use, clean your bucket so it won’t corrode, and build-up does not occur.

Lubricate Moving Parts: Keep the bucket pins and moving parts lubricated to lessen friction and wear. Doing that will help the machine run more smoothly and prevent long-term damage.

Store Properly: Store your bucket somewhere dry and out of the elements when unused so it doesn’t rust.

Conclusion

Using the right bucket, your mini excavator’s efficiency and effectiveness can be significantly increased. If you take the time to understand the strengths and uses of various buckets—how the digging bucket is the all-purpose excavator, the tilting bucket for maximum control—then you’ll know what tool to use for the job, and you’ll keep your buckets in tip-top shape so they’ll last longer and perform at peak. Furthermore, keeping up with regular inspections, cleaning, and lubrication will also help you save time and money on repairs and replacements.

For more information on reliable mini excavator equipment, check out TYPHON Machinery and explore options tailored to your projects. Additionally, USA Excavator offers a wide range of buckets and accessories to enhance your machine’s functionality. Machinery Asia is an excellent resource for excavator tools and insights if you’re working internationally. For detailed technical information and comparisons, visit Machines Wiki.

By investing in high-quality buckets suited to your needs, you will be able to do the most you can of your mini excavator to get your projects running smoothly.